Main Products

- Phosphonates Antiscalants, Corrosion

Inhibitors and Chelating Agents - Salts of Phosphonates

-

- Tetra Sodium Salt of 1-Hydroxy Ethylidene-1,1-Diphosphonic Acid (HEDP•Na4)

- Tetra Sodium Salt of 1-Hydroxy Ethylidene-1,1-Diphosphonic Acid (HEDP•Na4)

- 2-Phosphonobutane -1,2,4-Tricarboxylic Acid, Sodium salt (PBTC•Na4)

- Penta sodium salt of Amino Trimethylene Phosphonic Acid (ATMP•Na5)

- Hepta sodium salt of Diethylene Triamine Penta (Methylene Phosphonic Acid) (DTPMP•Na7)

- Potassium Salt of HexaMethylene-DiamineTetra (MethylenePhosphonic Acid) HMDTMPA•K6

- More

- Polycarboxylic Antiscalant and Dispersant

- Biodegradable Antiscalant and Dispersant

- Biocide and Algicide

- Built Scale & Corrosion Inhibitors and Pretreatment Filming Agents

-

- TH-907 Non-P Scale&Corrosion Inhibitor

- TH-503 Scale and Corrosion Inhibitor for Boiler

- TH-503B Scale and Corrosion Inhibitor for Boiler

- TH-504 Scale and Corrosion Inhibitor for Heating Water

- TH-601 Scale and Corrosion Inhibitor for Iron & Steel Plant

- TH-604 Scale and Corrosion Inhibitor for Power Plant

- More

- Corrosion Inhibitor

- Oxygen Scavenger

- Reverse Osmosis Chemicals

- Other

Shandong Taihe Technologies Co., Ltd.

TEL: +86-632-5113066

FAX: +86-632-5112055

E-mail: info@thwater.net

ADD: No.1, Shiliquan East Road, Shizhong District, Zaozhuang City, Shandong Province, P.R.China

Sodium Diethylhexyl Sulfosuccinate

Synonyms: Penetrant OT, Penetrating agent T CAS NO.: 1639-66-3

Molecular formula: C20H37NaO7S Molecular weight: 444.56

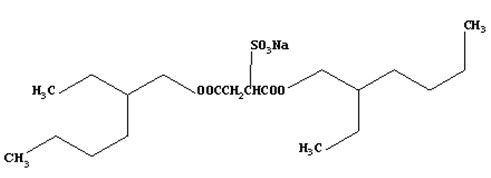

Structural Formula:

Properties:

This product is an anionic surfactant, it has properties of rapid penetration, homogeneity, wetting, emulsification and better frothing. It is intolerant with strong acid, strong alkali, heavy metals and reductant.

This product is soluble in water, lower alcohol, benzene, ccl4 and kerosene oil solvents. The solution is milk white, pH (1% water solution) is 5.0-7.0.

This product can penetrate rapidly and homogeneously, and has good effect at temperature lower than 40℃ and pH 5-10. The treated fabric is stable even temperature acidic and alklic condition changed. It’s widely used textile & dyeing, pesticide emulsification, tanning and mineral separation.

Specification:

| Items | Index |

|---|---|

| Appearance | Colorless to yellow viscous liquid |

| pH (1% water solution) | 5.0-7.0 |

| Penetrating (1% water solution) /s | 5.0 max |

| Solid content % | 50.0 min |

Methods and used in

(1) Cotton wool dyeing: 2g/l of this product is heated from room temperature to 95℃, 20 min dehydration, then rolling drift after cooling, cleaning, dechloridation.

(2) Cotton wool desize:cotton wool is pretreated at 20℃ for 5 min, then other additives can be added, it is heated to 80-90℃ in 20-30 min, and is treated for 45 min. When cotton shell is removed, it can be dyed. The preferred dosage is 2-3g/l.

(3) Cotton wool desize, bleach and dyeing: The direct or active dye which is oxidant tolerance is selected. The method is the same as 2, dyeing is added directly.

(4) Scouring of adhesive: addition of penetrant t in scouring of adhesive can reduce 2 h and decrease damage to silk.

(5) Usage in asbestos: for froth asbestos, the preferred dosage is 10-15% of asbestos; for dustless asbestos, the preferred dosage is 15-20% of asbestos.

(6) Usage in tanning: for dry tanning, this product is usually mixed with jfc, and the preferred dosage is 0.5-1.0%. For tanning additives, the preferred dosage is 10%.

Package and Storage:

Package: 200L plastic drum, IBC(1000L),customers’ requirement.

Shelf life: two years.

Attentions

(1) Sodium Diethylhexyl Sulfosuccinate has good penetrating performance under 40℃, it may decompose with alkali at high temperature condition. Thus, the fabric is recommended to be treated with Sodium Diethylhexyl Sulfosuccinate under 40℃ before heating up. For the production of asbestos products, there is no influence to the product by making the asbestos to pulp under 40℃ then heat to 200~300℃.

(2) This product is intolerant with strong alkali. Diluted with water first.

(3) This product is anionic surfactant, it cannot mixed with cationic surfactant or cationic dye.

(4) When raw blanks are being scoured and bleached, the slurry is recommended to be desized completely first to ensure the penetration effect.

(5) If too many froth is occurred, antifrother such as octanol, tributyl phosphate can be used.

Synonyms:

Penetrant OT

Penetrating agent T

Rapid Penetrant T

Sodium Diethylhexyl Sulfosuccinate

Sodium di-sec-octylmal-eacesulfonate

Butanedioic acid, sulfo-, 1,4-dioctyl ester, sodium salt

Succinic acid, sulfo-, 1,4-dioctylester, sodium salt

Succinic acid, sulfo-, dioctyl ester, Na salt

Octyl alcohol,sulfosuccinate (1:2) sodium salt

Sodium di-n-octyl sulfosuccinate

butanedioic acid, 2-sulfo-, 1,4-dioctyl ester, sodium salt

Dioctyl sulfosuccinate, sodium salt

sodium 1,4-bis(2-ethylhexyl) sulfosuccinate